In modern manufacturing, precision molds are the cornerstone of producing high-quality, uniform parts that meet exact specifications. Regardless of the industry automotive, electronics, medical devices, or consumer goods precision molds provide consistent results, ensuring each production run delivers a flawless fit and professional finish.

Why Precision Molding Matters

Precision molding is more than just shaping materials; it is about delivering tight tolerances, dimensional accuracy, and a smooth surface finish every time.

Benefits of precision molds include:

- Consistent product quality

Uniform components reduce variability and ensure reliability across every batch.

- Reduced material waste

Tight mold design minimizes excess material use, saving costs and reducing environmental impact.

- Lower rejection rates

Uneed improved accuracy means fewer defective units, boosting overall yield and profitability.

- Scalability for mass production

Once the mold is perfected, it supports high-volume manufacturing with minimal adjustments.

Key Features of High-Quality Precision Molds

When engineered correctly, precision molds incorporate advanced features that support long-term efficiency and excellence.

Essential attributes of precision molds:

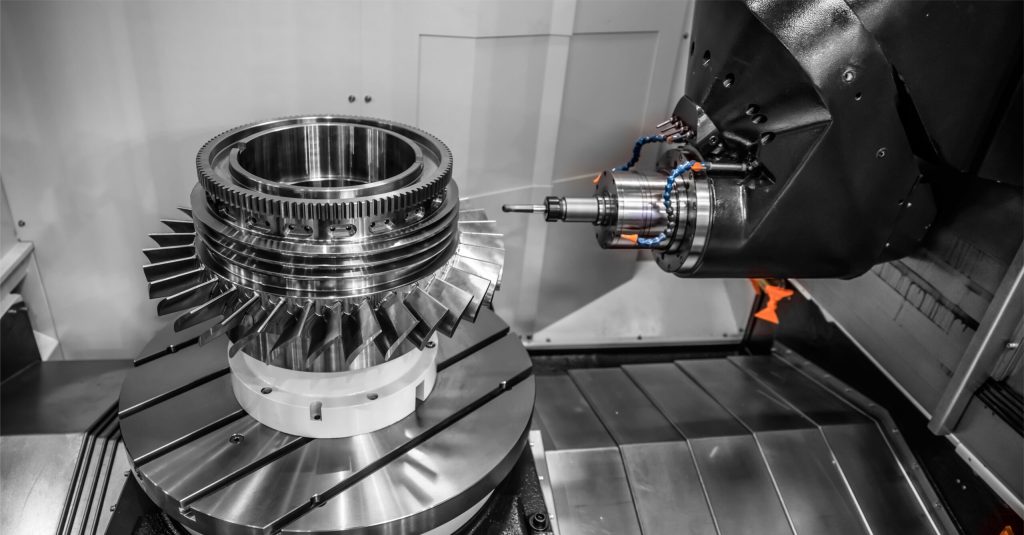

- High-grade tool steel construction

Durable materials extend mold life and maintain shape under high pressures and temperatures.

- Fine surface detailing

Enhanced surface textures for final parts, reducing the need for secondary finishing processes.

- Tight tolerances

Accuracy down to microns ensures parts fit together seamlessly without adjustment.

- Custom cavity design

Optimized layouts allow multiple parts per cycle without compromising uniformity.

Applications Across Industries

Precision molds are used in industries where dimensional accuracy and repeatability are non-negotiable.

Common applications include:

- Medical devices – for components requiring strict hygiene and precision

- Consumer electronics – where fit and finish impact both aesthetics and performance

- Automotive parts – ensuring proper mechanical function and durability

- Packaging – for consistent sealing, closure, and product integrity

How Precision Molds Improve Production Efficiency

Modern manufacturers rely on precision molds to streamline operations and maximize ROI.

- Shorter cycle times

Efficient cooling systems and optimized gating reduce mold cycle durations.

- Less post-processing

With perfect surface finish and dimensions, additional machining or polishing is minimized.

- Improved assembly line compatibility

Consistent part dimensions ensure smooth integration in automated systems.

Choosing the Right Mold Partner

To fully realize the benefits of precision molding, it is crucial to work with experienced mold designers and fabricators. From initial prototyping to final production, expertise makes a measurable difference in performance and reliability. If you are seeking world-class molding capabilities tailored to your production goals, look for solutions that combine engineering precision, quality materials, and responsive service.

Conclusion

Precision molds are indispensable to achieving a perfect fit and finish across every production run. By investing in the right mold design and production process, manufacturers can enhance product integrity, reduce waste, and maintain consistency at scale.